With a focus on ergonomic design- including an all-new cab, modular machine structure and ground-level servicing access, the new Volvo J-Series Articulated Haulers deliver refined performance, leading-edge technology and operational savings.

The J-Series concept includes the highly efficient Volvo drivetrain, diff-lock system and frame concept giving the best terrain mobility irrespective of weather conditions, maximized availability, and life-cycle productivity.

The unique Volvo hydro-mechanical steering system further enhances stability during high-speed operation. And in the A45 and all-new A50 models, a new transmission system increases durability and comfort with super smooth gear shifting.

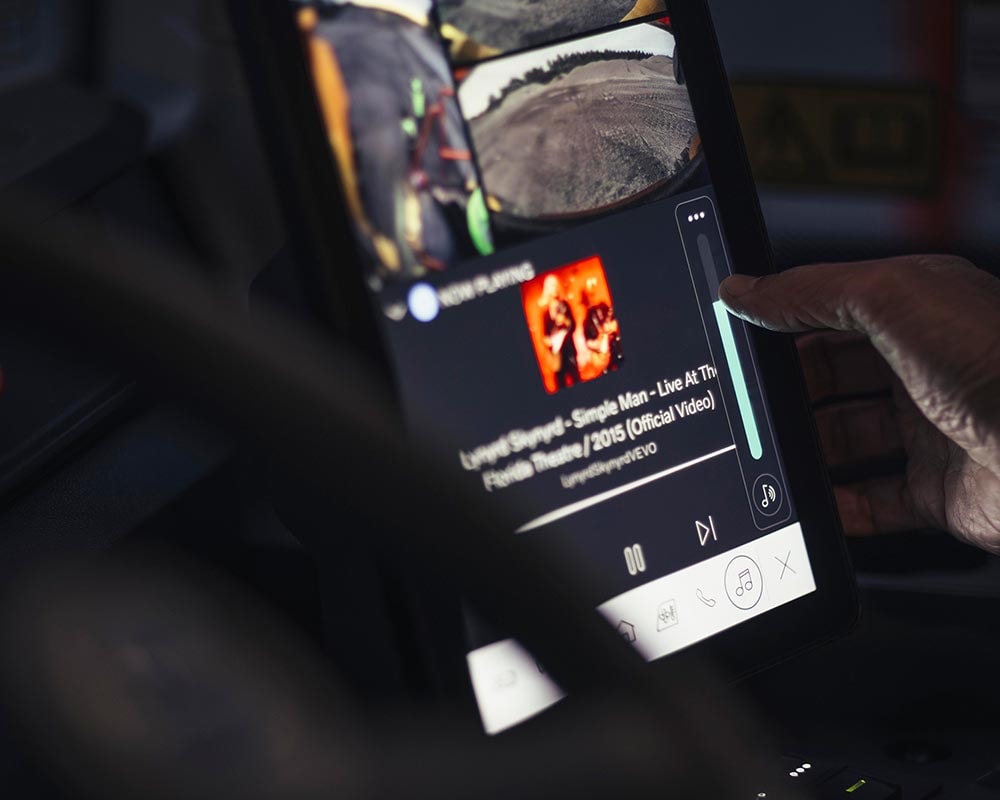

Operators can stay in-the-know and focussed on the task at hand thanks to all essential in-cab information conveniently displayed on just two screens. The interactive, integrated Volvo Co-Pilot display offers easy control over essential functions such as media, camera settings, climate control, and machine status. This is combined with the dynamic instrument cluster, positioned in front of the steering wheel, which provides essential vehicle data at a glance.

Enter and exit the with safety and ease thanks to the repositioned door entrance, which allows the door to be comfortably opened while standing on the roomy platform. Railings on both sides of the machine further add to the safe access, while the new entrance light guides operators up the stairs without glare or discomfort. Focused lighting further ensures clear visibility on both the stairs and platform.

Experience a new level of operator comfort and convenience when you step inside the comfortable, customizable and low-noise cab. With more storage, a cool/heat box, new premium seat options and enhanced connectivity - including Bluetooth connection, USB sockets, four speakers and a microphone - operators will enjoy an in-cab experience like no other. Simplify cleaning with hanging pedals and rear drainage for effortless dirt and debris removal, while the redesigned floor mat, now in three separate pieces, facilitates easier handling and cleaning.

The new ergonomic gear lever effortlessly returns to the center position after use. The result is a smoother operation, reducing operator strain and enhancing comfort and operator productivity during long work shifts.

The durable rubber suspension as standard provides outstanding off-road stability and reduced maintenance, ensuring a smooth ride even over the toughest terrain. The optional hydraulic suspension is the optimum choice when working on rough haul roads, providing versatility, performance and comfort across diverse operational scenarios.*

* Availalble for the A35, A40 and A45 models. A50 offers hydraulic suspension only.

Features including hill assist, cruise control, downhill speed control, load and dump brake and dynamic Volvo Engine Brake help operators achieve optimum results all day, every day.

Haul Assist, powered by the integrated Volvo Co-Pilot, is a set of tools designed to help you get even more productivity and efficiency from your Volvo Articulated Hauler. A key feature of Haul Assist is On-Board Weighing, which provides real-time payload information which can help to eliminate carry-back and overloading. The result is peak productivity, reduced fuel consumption and less machine wear.

With redesigned cab panels and wider wiper coverage, operators benefit from a direct field of vision which exceeds industry standards. Optional work lights activated via the integrated Volvo Co-Pilot are now located on the pillar, providing increased illumination ranging from 1800 to 2000 lumens per light to further optimize visibility. Visibility is further enhanced by the optional front and rear cameras, and standard entrance camera; camera views are easily managed using Volvo Co-Pilot, with options for both automatic and manual control of displays.

Ambient lighting surrounding the exterior of the machine enhances visibility, particularly in low-light conditions and during nighttime operations. The result is enhanced safety and accessibility for those working in the machine's service areas. A new entrance light guides operators up the stairs, for a safer machine entrance/exit.

Unlock the full potential of your Volvo Articulated Hauler with a range of operator training initiatives designed to help operators get the most from their Volvo machine.

The Volvo Articulated Hauler delivers unbeatable off-road performance in its class with features including the proven Volvo drivetrain, automatic drive combinations (including 100% differential locks), all-terrain bogie and hydro-mechanical steering for unmatched traction, stability and precision control. With Volvo Dynamic Drive, dynamic and predictive gear selection adapts to the operating conditions at hand, for improved comfort and fuel efficiency.

Experience superb fuel efficiency without compromising on power and performance thanks to the world-renowned Volvo drivetrain, including Terrain Memory*. The intelligent function identifies and remembers slippery road segments to ensure optimized traction control and outstanding off-road mobility.

* In markets with CareTrack

Make your daily job easier with downhill speed control. The function automatically maintains a constant speed when operating on downward gradients and is the perfect alternative to the retarder pedal for a more efficient and comfortable shift. Further optimize safety and performance with our best in class braking and retarder systems, including the Volvo engine brake, downhill speed control function and wet brakes on all wheels.

Move more for less thanks to the intelligent design, which is optimized for maximum efficiency in high payload applications. What’s more, work safely and productively thanks to the outstanding tipping stability.

Connected Map improves traffic flow and safety by providing real-time equipment locations, while Performance Indicator helps reduce fuel consumption and idle time by monitoring vehicle performance. Combined, these digital solutions increase productivity, promote efficient decision-making, and ensure smoother, safer operations.

Keep service costs to a minimum thanks to simplified servicing, longer change intervals and easy component access. Servicing your machine is quick and easy thanks to industry leading service access and essential maintenance points accessible from the ground. What's more, eliminate daily or weekly greasing thanks to industry leading greasing intervals of 250 hours for maximum uptime.

When measured over the lifetime of the machine, Volvo Articulated Haulers require less fluid volume compared to the competition, benefitting the environment and reducing operating costs. Fluid levels are constantly monitored with timely service alerts displayed on the operator displays, helping you stay on top of your maintenance requirements.

Maximize uptime, reduced unexpected repair costs and keep your machine operating in top condition with a Volvo service contract. With a service contract your Volvo dealer provides scheduled servicing, proactive diagnostics and expert support, to keep your operation running to its full potential. Choose from a range of flexible options designed to suit your requirements.

Work harder for longer with the reinforced axles, which withstand heavier loads, higher levels of torque and stress. The added strength and stability provided by the axles contributes to higher uptime, reduced wear, longer service intervals and lower maintenance costs.

Conveniently located at the ground level, the electrical service centre features a service switch (including Lock Out Tag Out) and provides easy access to check, charge, or help start the batteries. It includes a power down switch for proper system shutdown and also allows waking up of the machine, with functions including entrance and welcome lights, hood control and door open.

An electric priming pump eliminates manual pumping, along with a larger water bowl, which reduces the need for frequent draining. The pre-filter and main filter are grouped for easy access, reducing service points from two to one, shortening service time.

The cab now includes harness anchor points on the cab to ensure safety, withstanding a force of at least 22kN (2,268kg - 5,000lbs). This new safety feature aligns with WorkSafeBC OHS Regulation Part 11, ISO 14567:1999, and OSHA 1919.140(c) standards, optimizing safety and meeting regulatory requirements.

Haul Assist, powered by the integrated Volvo Co-Pilot, is a set of tools designed to help you get even more productivity and efficiency from your Volvo Articulated Hauler. A key feature of Haul Assist is On-Board Weighing, which provides real-time payload information which can help to eliminate carry-back and overloading. The result is peak productivity, reduced fuel consumption and less machine wear.

Connected Map improves traffic flow and safety by providing real-time equipment locations, while Performance Indicator helps reduce fuel consumption and idle time by monitoring vehicle performance. Combined, these digital solutions increase productivity, promote efficient decision-making, and ensure smoother, safer operations.

With the machine's new software architecture, you can adapt to changing needs and seamlessly incorporate future upgrades and new smart solutions. Our new electronic platform is not just an upgrade, it's a future enabler, ensuring your equipment stays up-to-date with cutting-edge technology.

Maximise machine uptime and reduce repair costs with the CareTrack telematic system. Choose to keep track of your machine yourself or let us take care of it with ActiveCare. Our Volvo Uptime Center will provide 24/7 machine monitoring, supplying weekly reports and notifying you should preventive maintenance action be required. Easily connect, locate and monitor your Volvo construction machines anywhere, on any device, using the My Equipment app by Volvo CE.

Make on-site logistics more efficient and lower your cost per tonne with the Site Optimization consultancy service. Our experts will visit your site and collect the data needed to assess the current situation and to find areas for further improvements. Simulations and reports will give insights to help you become more profitable while reducing your carbon footprint, while also improving accuracy in planning, forecasts and budgets with projections of your total haulage cost.