TDX now offer a complete lineup of FUCHS material handling solutions, backed by our nationwide support, service, and parts network.

The FUCHS range of material handlers is renowned worldwide for precision, durability, and innovation in material handling technology. Designed specifically for scrap, recycling, timber, port, and industrial applications, these machines combine high-performance hydraulics, ergonomic operator environments, and exceptional stability.

The FUCHS range offers tailored solutions to meet diverse handling challenges and delivers consistent productivity, low operating costs, and environmentally conscious efficiency.

Unload trucks in just a few cycles with smooth, precise handling - engineered for maximum efficiency in timber operations. The ability to comfortably handle high lifting powers makes FUCHS machines unbelievably versatile and extremely stable. With speeds of up to 20 km/h (12.4 mph) the FUCHS material handlers open up new dimensions in loading and unloading of trucks.

Scrap handling involves heavy-duty loading—and that is a weighty reason to count on FUCHS material handlers. With their legendary ruggedness and stability, they are ideal for deployment in routine scrap handling operations. Highly durable steel structures and an extremely solid undercarriage make for stability, while the powerful hydraulics ensure that even the heaviest loads are handled with ease and speed.

Efficiency, flexibility, performance, resilience: all attributes that feature the top of any wish-list when it comes to mobile material handlers deployed in the recycling industry. FUCHS machines offer everything that is needed for effective, high-volume handling on open terrain or in an indoor setting. Design features like the unique high-performance cooling system with separate coolers make FUCHS loaders ideal for dusty environments

The highly flexible and customised FUCHS material handlers are the ideal equipment for today's professional port handling. Substantial grabs, extensive working range, powerful and precise hydraulics permit record loading times. Thus, the FUCHS king-size powerhouses are suited to deployment across diverse applications, constituting an optimal link between ship, road transport, train, conveyor belt and storage facility—in accordance with the user's requirements.

Industry Applications:

The MHL320 has been the benchmark in industrial waste recycling for years. Double-edged cylinder bearings on the entire boom, a high-performance cooling system with physically separated coolers and the double row ball bearing slewing ring ensure exceptional durability and make the MHL320 the first choice in industrial waste recycling.

Enquiry Download Brochure

Industry Applications:

The MHL335 combines all the advantages of its little sister MHL331 and supplements it with an enlarged undercarriage. The support base of 16'9'' x 14'1'' provides extra stability when maximum loads are frequently moved at the maximum reach.

Enquiry Download Brochure

Industry Applications:

Thanks to individually adjustable operator settings, the machine can be perfectly customized to personal preferences. From control sensitivity to speed - everything can be fine-tuned precisely. At the same time, the smooth and well-balanced control ensures better handling and an even more pleasant operator experience in the cab.

Enquiry Download Brochure

Industry Applications:

Thanks to individually adjustable operator settings, the machine can be perfectly customized to personal preferences. From control sensitivity to speed - everything can be fine-tuned precisely. At the same time, the smooth and well-balanced control ensures better handling and an even more pleasant operator experience in the cab.

Enquiry Download Brochure

Industry Applications:

Even more power, even less fuel consumption - and that's not all: With state-of-the-art hydraulics, efficiency-increasing recuperation and an extremely comfortable cab, the MHL360 sets standards in modern material handling. With the combination of power and low emissions, as well as the equally high-torque and sensitive hydraulics, even demanding loading tasks can be carried out efficiently. The MHL360 offers maximum handling volumes with minimum loading times. The combination of a maximum reach of 59' and a closed swivel circuit make the MHL360 the first choice for e.g. loading stationary shredders and for loading and unloading smaller bulk carriers.

Enquiry Download Brochure

Safe place for daily checks and maintenance.

Metal pipes, great longevity.

For engine and hydraulic oil coolers.

Optimal distribution of force, high longevity, less wear and tear.

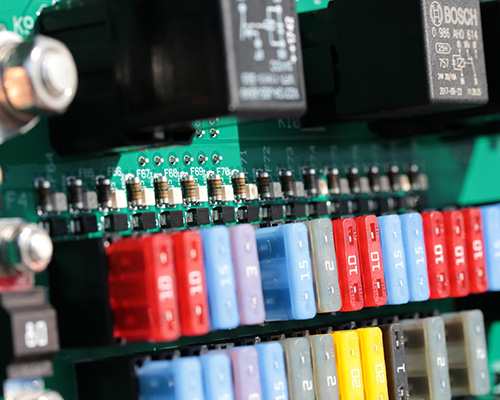

Fuses can be checked quickly and easily.

Hose rupture safety valves with regeneration function as standard from the MHL360 to the F120 MH.

Touchscreen LCD display: the dashboard provides all important information at a glance.

Parameters can be easily fine-tuned to your personal preference.

Internally geared double row slewing ring bearing, greasing via automatic lubrication system.