THE MIRACLE OF THE MULTI-GRADE

We’re all familiar with multi-grade diesel engine oils. Viscosity is one of two characteristics which we use to fully describe an engine oil. The other is performance, whether an API Service Classification, an ACEA Classification or an OEM specification. Any lubricant, including diesel engine oils, can be fully described by those two functions, performance and viscosity. Probably the most common multi-grade viscosity classification we encounter is an SAE 15W-40, though some modern diesel engines are now calling for SAE 10W-40, SAE 5W-30 or even SAE 0W-20 viscosity engine oils..

A multi-grade engine oil is a technological marvel, yet we tend to take them for granted. It provides the appropriate fluid film protection in a number of flow and temperature conditions, being cranked at cold start-up temperatures down as low as -35o C, circulating as the bulk engine oil at around 100o C, or being torn apart through the ring belt area at temperatures around 185o C. And a multi-grade engine oil has to survive all these different conditions.

The Society of Automotive Engineers (SAE) was formed in 1905. In 1911 it established its viscosity grade classifications for engine oils. This first SAE Viscosity Grades for Engine Oils classification was for ‘straight’ monograde engine oils. It was common in areas with large summer to winter temperature variations for an engine to be run on a less viscous oil grade, such as SAE 10, in winter and on a thicker SAE 30 in the summer.

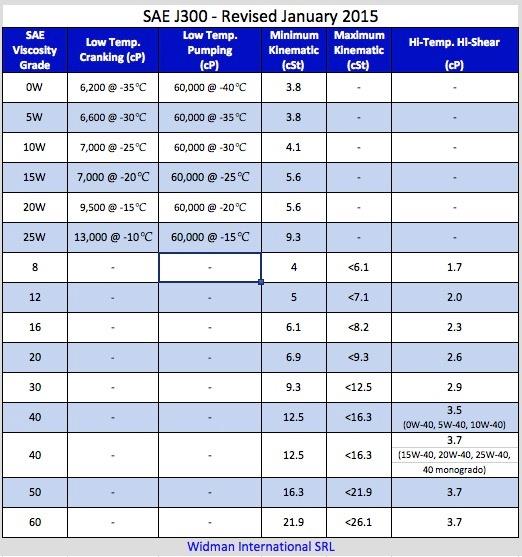

These days the SAE publication J300 Viscosity Grades for Engine Oils defines engine oil viscosity grades by four different viscosity tests. SAE viscosity grades are divided into two distinct groups. There are the “W”/winter, grades of engine oil and the straight high temperature viscosity grades (the “non-W” viscosity grades).

The “W”/winter viscosity grades describe the oil’s viscosity under cold temperature engine starting conditions. There’s a Low Temperature Cranking Viscosity which sets a viscosity requirement at various low temperatures to ensure that the oil isn’t too thick so that the starter motor can’t crank the engine over. As well, there’s a Low Temperature Pumping Viscosity which ensures that the oil at low temperatures isn’t so thick so that the oil pump cannot move it. “W”/winter grades also have to meet a minimum high temperature viscosity.

The “non-W”, high temperature viscosity grades have their viscosity measured at high temperatures representative of the conditions that the oil encounters in an operating engine. Each “non-W” viscosity grade has a range of viscosities at 100o C which it must fall within. For instance, an SAE 30 must be between 9.3 and <12.5 cSt at 100o C, that’s the approximate temperature of the bulk oil in the engine oil circulating system. Then each “non-W” viscosity grade must also have a minimum High Temperature/High Shear (HTHS) viscosity, this is the viscosity of the oil measured at 150o C under high shear conditions where the oil is being squeezed between moving surfaces. That duplicates the conditions the oil finds in areas such as between the piston ring and cylinder, and between cam followers sliding on cam lobes.

So the two viscosity groups are completely different, the “W”/winter grades describe low temperature viscosity oil characteristics and the “non-W” viscosity grades describe high temperature viscosity oil characteristics.

The last update of J300 Viscosity Grades for Engine Oils in 2015 also introduced SAE 8, SAE 12 and SAE 16 high temperature viscosity grades. Low viscosity high temperature grades are becoming more common because of their contribution to fuel economy. A low viscosity oil takes less energy to circulate than a high viscosity oil and the lower viscosity oil will produce less drag between sliding surfaces.

The very early SAE Viscosity Grades for Engine Oils defined only one condition of the oil, its viscosity at engine operating temperature, and ‘straight’ SAE monogrades ran from SAE 10 to SAE 50. But these early monograde engine oils had problems. In winter in the U.S.A. it was found that engines could just not be cranked over at the low temperatures that were experienced.

That’s why the SAE developed “W”/winter, grades of engine oil. This led to the introduction of SAE 10W, 15W, 20W and 25W low temperature viscosity grades. An engine would be run on SAE 30 engine oil in summer, and on an appropriate ‘W’ viscosity grade in the winter which would allow the engine to be cranked and started. Later, the SAE added the Low Temperature Pumping viscosity requirement to “W”/winter grade viscosity classifications because it was found that after long periods of cold soak at low temperatures the oil might not even be able to be pumped once the engine was started.

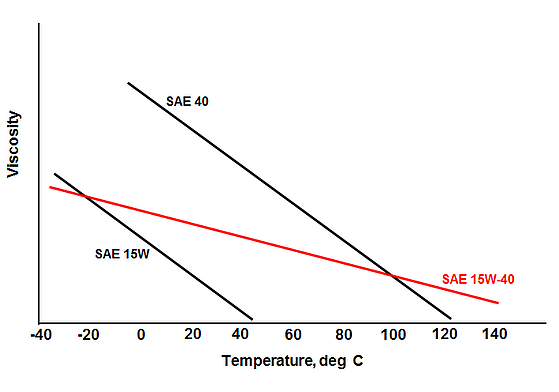

In the mid-1950s, oil industry chemists developed an oil additive called a Viscosity Index Improver (VII). Viscosity Index (VI) is a description of the rate at which oil will change viscosity as temperature changes, all oils thicken in viscosity as temperature drops and thin in viscosity as temperature rises, good quality virgin mineral oil has a VI of around 95 to 100. The newly developed Viscosity Index Improver (VII) additive changed the rate at which oil thickened as temperature dropped and thinned as temperature rose. An oil modified with a Viscosity Index Improver still thickens as temperature drops, but it doesn’t thicken as much as a non-modified oil. Nor does it thin out as much as the temperature rises.

In the late 1950s, the first multi-grade engine oils were introduced. Most of these were SAE 10W-30 multi-grades, they met the low temperature engine cranking viscosity requirements of an SAE 10W grade plus the high temperature oil circulation viscosity requirements of an SAE 30 grade. Two oils for the price of one!

But how does a Viscosity Index Improver (VII) create a multi-grade, producing a single engine oil which can meet the SAE requirements for a low temperature oil, and at the same time meet the requirements of a high temperature oil?

What we have to remember is that viscosity is just “resistance to flow”, a thin oil flows easily, a thick oil flows slowly – water has a low resistance to flow and is low viscosity, treacle has a high resistance to flow and has a high viscosity. When specifying a viscosity, and because oils change viscosity with change in temperature, we have to state at what temperature a viscosity applies. The high temperature viscosities for engine oil are measured at 100o C because that is the approximate temperature of the oil in an engine sump. HTHS viscosity is measured at 150o C because that is approximately the temperature in the ring belt area. Industrial oils have their viscosity specified at 40o C, because industrial hydraulic, gear and circulating oil systems will be operating around that temperature.

But, how do we produce a multi-grade engine oil using a Viscosity Index Improver (VII) additive, say a mineral oil based SAE 15W-40? Synthetic oils have naturally high Viscosity Indices (VIs), they are naturally multi-grade oils without having to have a Viscosity Index Improver (VII) added to them. We start with a lower viscosity mineral oil which meets the cold temperature cranking and low temperature pumping specifications of SAE 15W oil. Then the right volume of VII is added to produce the high temperature viscosity of an SAE 40 engine oil, and we end up with an SAE 15W-40 multi-grade. It all sounds simple, but it’s how the VII works that is the intriguing thing.

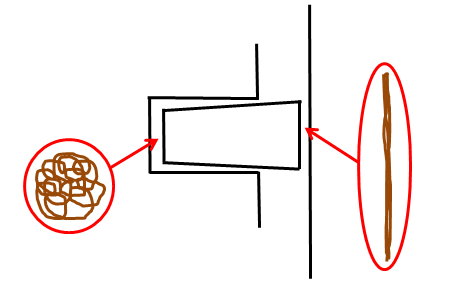

A Viscosity Index Improver (VII) additive is an organic chain molecule which is bundled up like a ball of spaghetti and dissolves in the oil. When cold the VII molecule shrinks and the oil has less resistance flowing passed – less resistance to flow, lower viscosity oil. When hot, the VII molecule swells and produces higher resistance to the oil flowing passed, the oil has still thinned out due to the temperature rise but now it has a higher viscosity than if the VII was not there.

Oil passes the viscosity index improver molecule when cold

Oil has difficulty passing the viscosity index improver molecule when hot

But it is across the small width of the piston ring that the real miracle of a multi-grade engine oil occurs. Across the piston ring, maybe just a distance of 5 mm, a multi-grade engine oil displays two completely different viscosity characteristics.

Multi-grade oil displays two different characteristics across the width of a piston ring

In the piston groove, the oil is not subjected to any sliding motion, the Viscosity Index Improver molecule isn’t distorted at all, it remains in its ball of spaghetti shape, the oil has a high viscosity and cannot move through the ring groove gap.

Yet on the outside of the piston ring, up against the cylinder wall and maybe only 5 mm away, the oil is subjected to high shear caused by the ring sliding up and down the cylinder wall. The Viscosity Index Improver molecule becomes stretched out like a long thin piece of string, the oil between the ring and the cylinder wall now has a low viscosity, the ring slides on an extremely thin layer of fluid and the oil cannot migrate up the cylinder wall and get lost as oil consumption. Also, because the oil in this contact area between the piston ring and cylinder wall has a low viscosity, friction is reduced and there is a slight gain in fuel efficiency.

Not only does a multi-grade engine oil allow low temperature starting and protect engine components in high temperature conditions, it also minimises oil consumption and contributes to improved fuel economy. All from a little molecule shaped like a ball of spaghetti which shrinks when it’s cold and swells when it’s hot. That’s the miracle of the multi-grade.